The Virtual Quality Assistant aims to automate in-line quality measurements. It uses AI models to measure quality characteristics such as dimensions, color, number of defects, type of defects, and dry matter content, all in-line. The results are then used to optimize process parameters or to visualize insights on a dashboard.

The Virtual Quality Assistant can be widely applied. Quality is important both upstream and downstream in production, and it can also be used for packaging inspection. We are already working with companies such as Agristo, Warnez Potatoes, Roger&Roger...

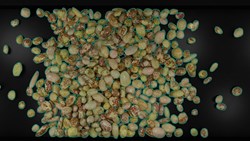

The biggest challenge in AI is the enormous need for high-quality data. Obtaining this data to train the models is very resource-intensive. Therefore, the Virtual Quality Assistant uses "synthetic" data. We simulate synthetic potatoes to train the models. This ensures that the models are highly robust and scalable.

If necessary, we implement a stand-alone hardware unit equipped with the required sensors. This unit is fully connected to existing systems to fully embed the solution into the process.

Date of market introduction in Belgium (if still in development: expected date of launch)

Jan 2024

Briefly formulate what is new. If your innovation is selected for inclusion in the innovation route, your text will be used as the basis for the texts in the communication to the visitors, press, etc... (max. textarea: 1000 characters)

The Virtual Quality Assistant goes beyond traditional vision techniques for measuring the dimensions of potatoes. Thanks to advanced models, we can also automatically measure the number and type of defects in-line. These AI models are trained using "synthetic" or simulated data, allowing for quick and scalable deployment. With these models, potatoes can be measured even when they are stacked in multiple layers. This ensures that the process itself does not need to be adjusted for the implementation of automated quality control.

Added value for the user (in commercial terms, user-friendliness ...)

The Virtual Quality Assistant also includes a dashboard for visualizing the results. Additionally, reports can be generated to document the quality of a specific batch.

Within a production process, the results can also be linked to the optimization of process parameters.

Added value for the further sustainability and professionalization of the potato sector.

By reducing the feedback loop between detecting a quality deviation and adjusting the process parameters, a significant reduction in waste is achieved. Additionally, the variation in potatoes will be measured and acted upon. This leads to more stable quality as well as higher overall quality.