The OPTICEPT® (Controlled Environment Pulsed Electric Field Treatment), is a state-of-the-art PEF-system developed by FPS Food Process Solutions in collaboration with PEF-specialists OptiCept Technologies. It is specifically designed for the solid food processing industry and brings distinct advantages to the potato sector.

PEF technology can improve quality and efficiency in the potato processing industry, in terms of products and processes. For example, PEF has shown significant advantages over conventional preheaters.

PEF treatment softens the potato tissue, minimizing breakage and feathering during cutting, resulting in more uniform fries and higher yield. The treatment requires less cutting force resulting in a smoother cut.

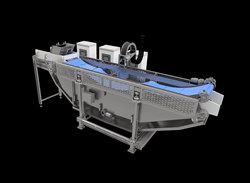

The patented OPTICEPT® system consists of a PEF generator and a conveyor belt system with a built-in PEF chamber.

The PEF generator is food grade compliant with the enclosure designed in stainless steel. All control and safety devices are included, as well as sensors for pressure, temperature, flow, and conductivity. The Dual Conveyor Belt System is hygienically designed focused on robust construction, cleanability, and high efficiency.

OptiCept’s PEF technology combined with FPS Food Process Solutions’ hygienic manufacturing and engineering design will be a game changer for food manufacturers.

Date of market introduction in Belgium (if still in development: expected date of launch)

End 2024

Briefly formulate what is new. If your innovation is selected for inclusion in the innovation route, your text will be used as the basis for the texts in the communication to the visitors, press, etc... (max. textarea: 1000 characters)

The OPTICEPT® is the most efficient PEF system to date, boasting minimal energy consumption. Its unique features ensure consistency, uptime, and minimal maintenance. PEF technology is more energy-efficient than traditional heating methods, operating at lower temperatures, using less water, and requiring less energy.

The patented PEF chamber design features a dual conveyor belt system, ensuring potatoes are fully submerged for optimal treatment. This design provides consistent processing compared to single conveyor systems.

The smart dual conveyor system maximizes energy efficiency with a higher fill grade, consuming less power than traditional single conveyors. Additionally, dual lift-up conveyors simplify maintenance and cleaning.

The system includes multiple generators operating below maximum capacity, allowing for maintenance without disrupting production. Built-in short-circuit protection ensures non-affected generators continue to operate, minimizing production downtime.

Added value for the user (in commercial terms, user-friendliness ...)

The OPTICEPT® system is scalable, based on production requirements. If greater production is required, adding another generator to meet production output can be included.

Added value for the further sustainability and professionalization of the potato sector.

The OPTICEPT PEF system ensures further sustainability through energy efficiency, less product waste, reduced water consumption, and a smaller carbon footprint in food factories. As the potato sector is considered one of the most universal products around the world, it is critical to optimize processing methods to ensure quality and quantity of this important food commodity.