ULTRAVENT® M - The modular filter system

Multifunctional. Powerful. Energy-saving.

M for modular - The adaptable procedural system for your application

Our solution for your exhaust air for configuration tailored to your needs

Exhaust gases and pollutants in the air are as different as their respective processes. Thanks to our many years of experience in exhaust air filtration we can meet the specific requirements for your application.

The individual configuration of your exhaust air filter system depends on the air volume, the pollutant concentration and the respective properties of the pollutants in your exhaust air. In addition, our solution takes the emissions specifications for clean air quality and the heat of the exhaust air into account. For more energy efficiency, the ULTRAVENT® M offers the possibility of recovering and utilising valuable process heat. Thanks to its powerful functional modules, the ULTRAVENT® M has an optimal solution ready for all challenges of modern exhaust air treatment.

Powerful functional modules for every challange

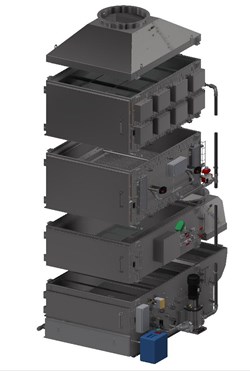

The ULTRAVENT® M consists of functional components which, as standardised modular components, can be flexibly configured according to its requirements. The modular design allows a scalable and integrated solution suitable for any application.

Depending on the equipment, ULTRAVENT® M contains an electrostatic precipitator for highly efficient particle separation. In addition, the system can be equipped with intelligent heat exchanger technology for powerful recovery of valuable process heat. For the effective separation of VOC and odours, KMA offers additional solutions with UV light modules and activated carbon.

Energy-efficient environmental technology for lower operating costs

Reduce your energy costs and CO2 emissions by over 90% compared to thermal post-combustion (TNV). The ULTRAVENT® M filters the exhaust air sustainably without afterburning and thus completely without the use of fossil fuels. In addition, the economical operation of the electrostatic particle filter module contributes to the ULTRAVENT® M's low energy consumption. At the same time, the use of the long-life filter cells is ecologically and economically more sustainable. Unlike mechanical filters they do not have to be renewed and discarded at additional cost. On top of that, the integration of high-performance heat exchanger modules allows effective recovery of process energy from the exhaust air with further significant energy savings. In this way, the energy-efficient KMA environmental technology combines tangible cost advantages with a verifiably improved ecological footprint.

Unique integrated cleaning system for all functional modules

Thanks to the integrated automatic KMA cleaning system (Cleaning in Place "CIP"), the ULTRAVENT® M is powerful, reliable and low-maintenance. The unique technology of the KMA CIP allows all relevant functional components to be cleaned automatically in place - from the energy-efficient heat exchanger modules to the electrostatic particle filter and the odour-neutralising UV light modules.

In addition, through e.g. optional automatic waste water management or automatic dosing of the cleaning agent, the service comfort for the user of the filter system can be increased. Our cleaning system convinces customers worldwide and minimises undesired downtimes of the production plant.

Date of market introduction in Belgium (if still in development: expected date of launch)

01.01.2024

Briefly formulate what is new. If your innovation is selected for inclusion in the innovation route, your text will be used as the basis for the texts in the communication to the visitors, press, etc... (max. textarea: 1000 characters)

Environmental technology to improve your carbon footprint.

ULTRAVENT M – The modular environmental technology system for potato processing

The potato processing industry is characterized to a large extent by energy-intensive processes that cause greasy emissions or unpleasant odours and are often accompanied by considerable amounts of waste heat. In the face of increasing regulatory requirements and growing environmental responsibility, companies must find ways to reduce their emissions and improve their environmental footprint. At the same time, energy costs are rising, making energy efficiency a decisive competitive factor. Innovative exhaust air purification systems enable effective compliance with emission limits or the reduction of odours, while at the same time reducing resource consumption and maintenance costs. By recovering waste heat from polluted process exhaust air, they make an important contribution to lowering energy consumption of and reducing CO2 emissions.

Added value for the user (in commercial terms, user-friendliness ...)

It is possible to reduce energy costs and CO2 emissions by over 90% compared to thermal post-combustion (TNV). The ULTRAVENT® M filters the exhaust air sustainably without afterburning and thus completely without the use of fossil fuels. In addition, the economical operation of the electrostatic particle filter module contributes to the ULTRAVENT® M's low energy consumption. At the same time, the use of the long-life filter cells is ecologically and economically more sustainable. Unlike mechanical filters they do not have to be renewed and discarded at additional cost. On top of that, the integration of high-performance heat exchanger modules allows effective recovery of process energy from the exhaust air with further significant energy savings. In this way, the energy-efficient KMA environmental technology combines tangible cost advantages with a verifiably improved ecological footprint.

Added value for the further sustainability and professionalization of the potato sector.

Exhaust gases and pollutants in the air are as different as their respective processes. Thanks to our many years of experience in exhaust air filtration we can meet the specific requirements for the potato processing industry. In our process, the odorous exhaust air is not burned but it is filtered in a sustainable way. The heat of the exhaust air is recovered via a heat exchanger module and therefore not wasted. Instead, the thermal energy can be provided to other production processes, improving the energy efficiency of the whole production.

The individual configuration of the exhaust air filter system depends on the air volume, the pollutant concentration and the respective properties of the pollutants in the exhaust air. Thanks to its powerful functional modules, the ULTRAVENT® M has an optimal solution ready for all challenges of modern exhaust air treatment for potato processing.